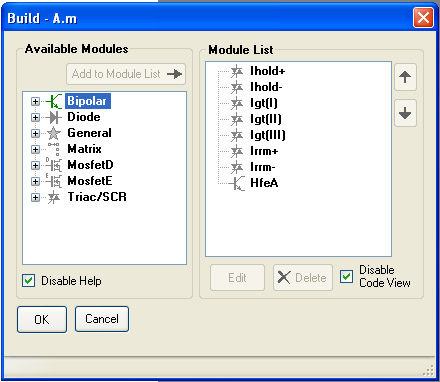

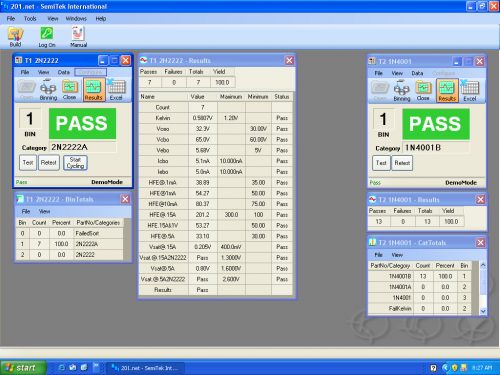

The 201.net is fully programmable to electrically test and ensure the integrity of discrete semiconductor devices. The system is modular in design with each stimulus module individually addressable for specific test requirements.

The system is PC powered and can connect to your local area network for control, program management, and data processing. Multiple systems can be networked to complete production applications.

The .net architecture makes the 201 and XTOS operating system the most versatile, simplistic, and economical, discrete semiconductor test system available in its class.

In its sixth generation, the 201.net is ideal for inspection and production applications where precision measurements are required.